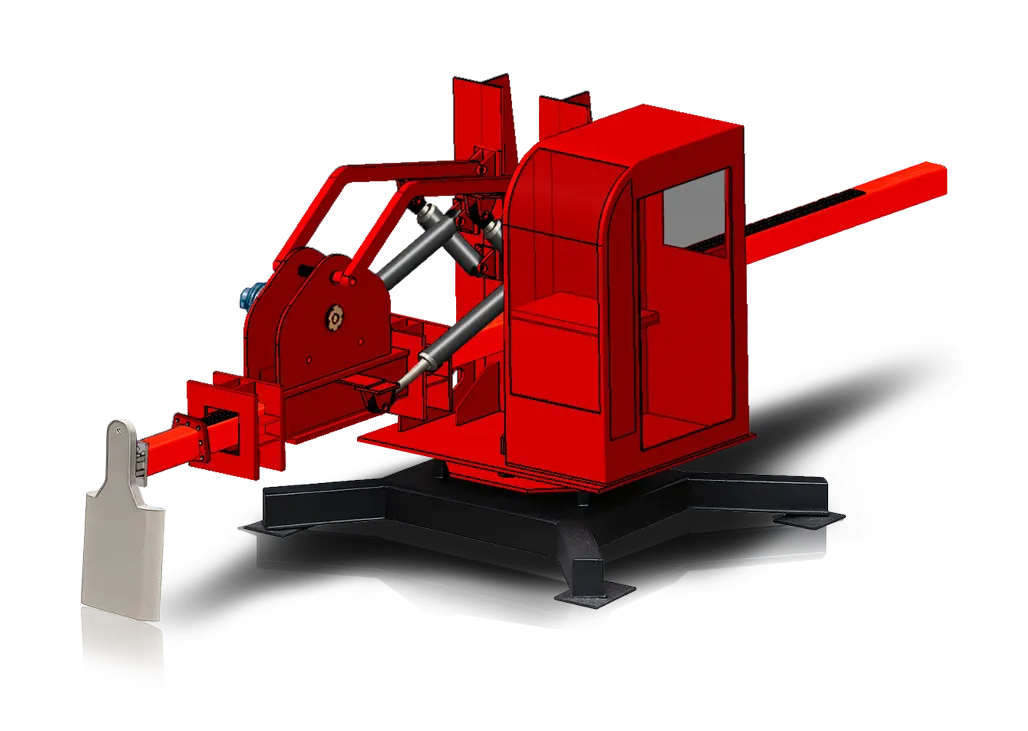

Slag Skimming Machine(SSM)

Slag Skimming Machine

SSM is used to remove the slag formed on the surface of the molten metal in the ladle KR/hot metal desulphurization process aluminum and copper furnaces. This equipment also comes with a telescopic wrecking arm which has forward and backward movement.

Features

Vertical lift and angular movement of the wrecking boom are available, personalized based on your needs!

- Power pack available off board and on board as per your request

- PLC panel available off board and on board as per your request

- Wrecking stroke and paddle are designed as per your request.

- Cabin comes with air-conditioning.

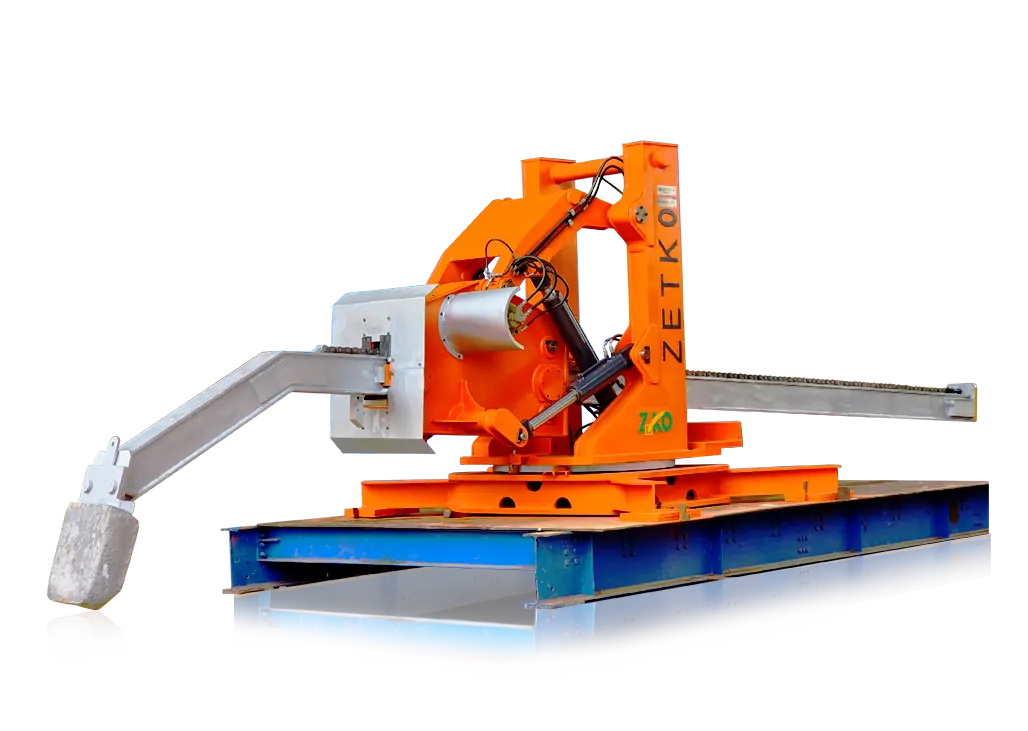

Slag Skimming Machine(SSM)

Zetko Telescopic Machines available with options Diesel or Electrical Power, Tyre or Crawler, with cabin or with remote or combined operations, Articulation or Non-articulation.

- On Board

- Off Board

On Board

- Parallel lift- 1-1.5 m

- Boom stroke: 2-8 m

- Racking speed: 0.2 – 2.5 m/s

- Power- 30-74 kW Comes with control desk, power pack PLC optional

Cabin Only On Board

- Parallel lift- 1-1.5 m

- Boom stroke: 2-8 m

- Racking speed: 0.2 – 2.5 m/s

- Power- 30-74 kW Comes with control desk, power pack PLC optional

Off Board

- Parallel lift- 1-1.5 m

- Boom stroke: 2-8 m

- Racking speed: 0.2 – 2.5 m/s

- Power- 30-74 kW Comes with control desk, power pack PLC optional

Blast Furnace Refractory Delining Machine

Complete solution of tap hole renewal for cylindrical or iso-jet sleeve design. All function is one equipment by one operator. It takes care of drilling of a worn out sleeve and inserts new sleeve.

Follow our YouTube channel

ZETKO

ZETKO- DKV TECHNIK(INDIA) PRIVATE LIMITED

ZETKO TECHNOLOGIES LLC. USA

(Formerly ZETKO MASCHINENBAU GMBH, GERMANY)

ZETKO TECHNOLOGIES LLC. USA

(Formerly ZETKO MASCHINENBAU GMBH, GERMANY)

Contacts

Phone:

+91 8688401799

+91 8297144476

E-Mail:

sales@zetko.us

bluesky@zetko.us