Taphole sleeve replacement technology-

Our CTRM helps with drilling the worn-out taphole and inserting a new taphole sleeve. It works with all types of taphole sleeves in the market: cylindrical, segmental, cylindrical monolithic, conical with block, conical monolithic and many more which can be personalized for you.

– Drilling of taphole within 5 to 10 minutes (depending on site conditions)

– Our twin drill head and technology

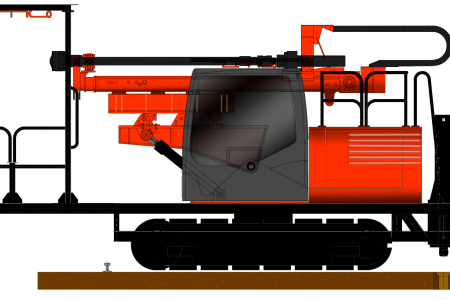

Zetko Telescopic Machines available with options Diesel or Electrical Power, Tyre or Crawler, with cabin or with remote or combined operations, Articulation or Non-articulation.

Operating Weight : 15 – 35 Ton

Power : 76 – 150 kW

Drill Torque : 4000 – 5000

Operating Weight : 15 – 35 Ton

Power : 76 – 150 kW

Drill Torque : 4000 – 5000

Operating Weight : 15 – 35 Ton

Power : 76 – 150 kW

Drill Torque : 4000 – 5000

Operating Weight : 15 – 35 Ton

Power : 76 – 150 kW

Drill Torque : 4000 – 5000

Operating Weight : 25 Tons

Power : 76 – 150 kW

Drill Torque : 4000 – 5000

Operating Weight : 24 – 28 Ton

Boom Stroke : 1 – 3 mts

Drill Torque : 7000 – 9000

Zetko has created a budget friendly, multipurpose technology taphole renewal attachment type (CRTM-A).

-If you do not wish to invest in two exclusive machines: you can invest in CTRM-A. This attachment is compatible with your existing telescopic boom wrecking machine and you existing EBTRM

– Drilling time: 15 to 20 minutes depending on the plant conditions .

It moves forward and backward and does not require TBWM boom rotation and boom stroke

– It can be interchanged within 5 minutes, with the use of our mechanical quick coupler for TBWM machines reducing downtime and increasing productivity. Other tools can also be attached to this coupler technology for different purposes

– Drill bits are provided based on the application needs: Solid drill bit, TC bits drill, fine cutter drills and many more.

– New taphole can be inserted using the resleeving attachment

– Zetko has created an economical solution to perform taphole drilling operation: Sundrilla, which ensures 100 % safety.

– This application can be used with new or existing Telescopic boom rotations for drilling. It also helps forward and backward movement for TBWM.

– Drilling time: 15 to 20 minutes

– This attachment is run by a hydraulic motor and does not need boom rotation for drilling.

– It can be interchanged within 5 minutes, with the use of out mechanical quick coupler reducing downtime and increasing productivity.

– Drill bits are provided based on the application needs: Solid drill bit, TC bits drill, fine cutter drills and many more.

We have two versions of machines for EBT operation. Our machine is a telescopic boom ladle debricking machine having Volcadrila attachment to perform EBT renewal.