News and customer case stories

Read the latest product news and stories.

Deslagging ensures efficient heat transfer & prevents build-up inside furnaces & ladles. Automated deslagging improves product quality, reduces refractory wear. …

Electric Arc Furnace (EAF) maintenance involves periodic renewal of the EBT (Eccentric Bottom Taphole), end plate replacement, and cleaning of …

The LD Converter accumulates slag, metal, and refractory buildup that must be cleaned regularly to maintain lining life and process …

Steel plant maintenance involves a comprehensive range of activities designed to keep all mechanical, electrical, and process systems running efficiently. …

Ladle cleaning is the removal of residual slag, metal, and refractory buildup inside a steel ladle after pouring. A clean …

The taphole in an LD/BOF converter allows molten steel to flow out. Over time, it wears out and must be …

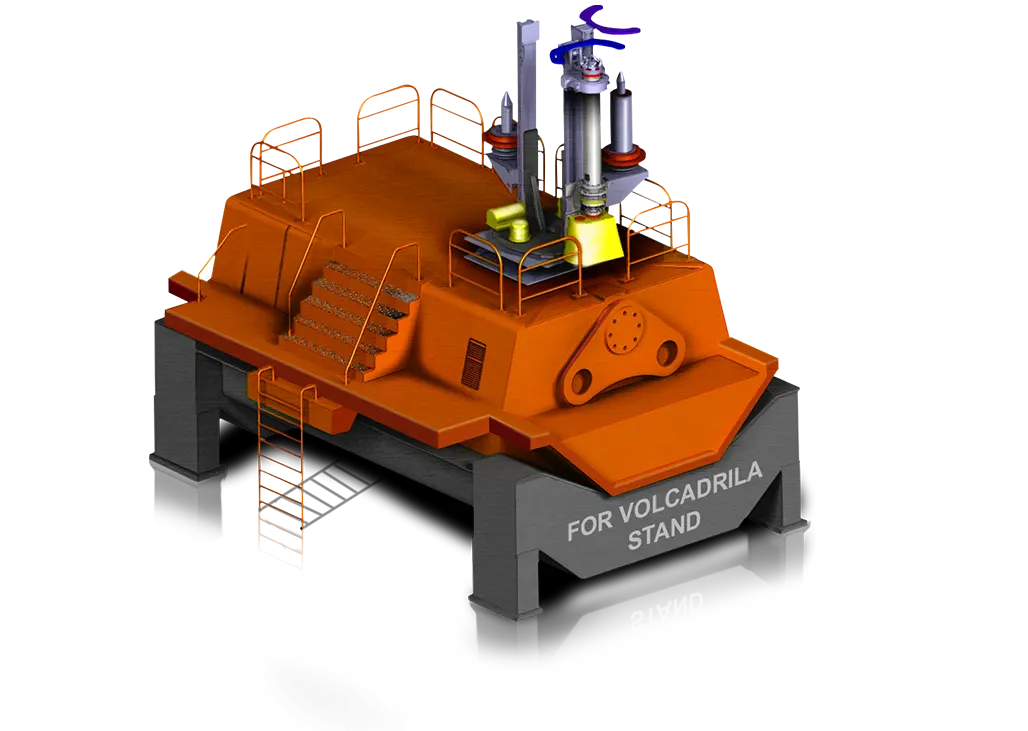

Our CTRM machine is suitable for drilling the worn-out Taphole sleeve and inserting a new Taphole sleeve. It works with …

Debricking is the process of removing damaged refractory linings from converters, ladles, and furnaces before relining. Manual debricking is unsafe …

The converter taphole zone demands exact handling. Misalignment or manual errors can compromise the mother block, leading to costly downtime …

Zetko is heading to METEC Southeast Asia 2025! Meet us to explore our latest innovations in slag skimming, furnace maintenance, …

Advancing Clean Air Solutions | ASSOCHAM x WRI India x JSW Steel x Zetko Zetko is thrilled to join hands …

Follow our YouTube channel

ZETKO

ZETKO- DKV TECHNIK(INDIA) PRIVATE LIMITED

ZETKO TECHNOLOGIES LLC. USA

(Formerly ZETKO MASCHINENBAU GMBH, GERMANY)

ZETKO TECHNOLOGIES LLC. USA

(Formerly ZETKO MASCHINENBAU GMBH, GERMANY)

Contacts

Phone:

+91 8688401799

+91 8297144476

E-Mail:

sales@zetko.us

bluesky@zetko.us