Converter Tap hole Renewal Machine

Converter Tap hole Renewal Machine(CTRM)

Exclusive converter (BOF) taphole renewal machinery CTRM

Taphole sleeve replacement technology-

Zetko CTRM helps with drilling the worn-out taphole and inserting a new taphole sleeve. It works with all types of taphole sleeves in the market: cylindrical, segmental, cylindrical monolithic, conical with block, conical monolithic and many more which can be personalized for you.

- Drilling of taphole within 5 to 10 minutes (depending on site conditions)

- Our twin drill head and technology

Converter Tap Hole Renewal Machine

Zetko Telescopic Machines available with options Diesel or Electrical Power, Tyre or Crawler, with cabin or with remote or combined operations, Articulation or Non-articulation.

- CTRM

- BK 2000

- Sundrila

CTRM A

Sundrilla (Taphole Drilling Attachment)

CTRM A

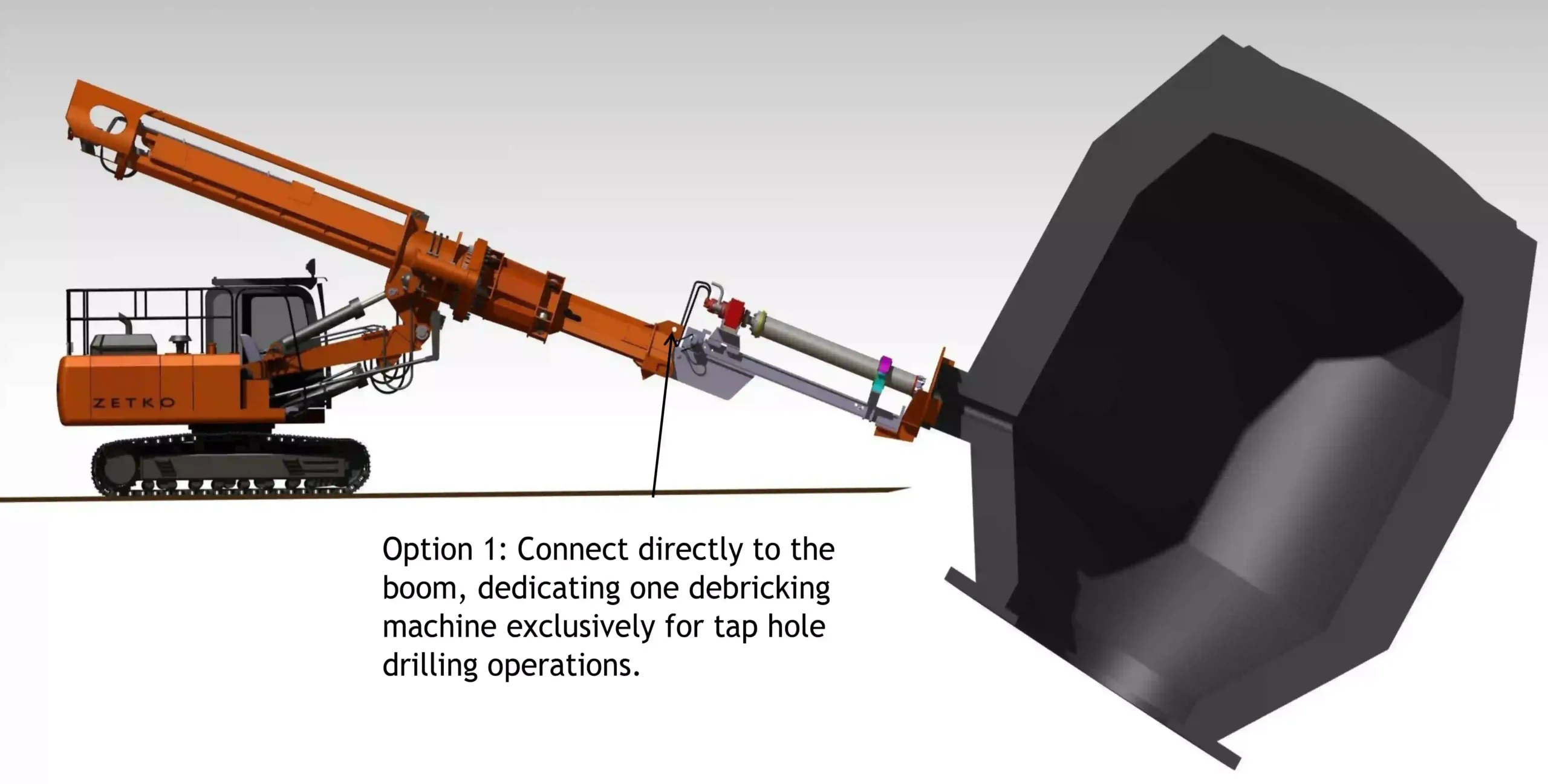

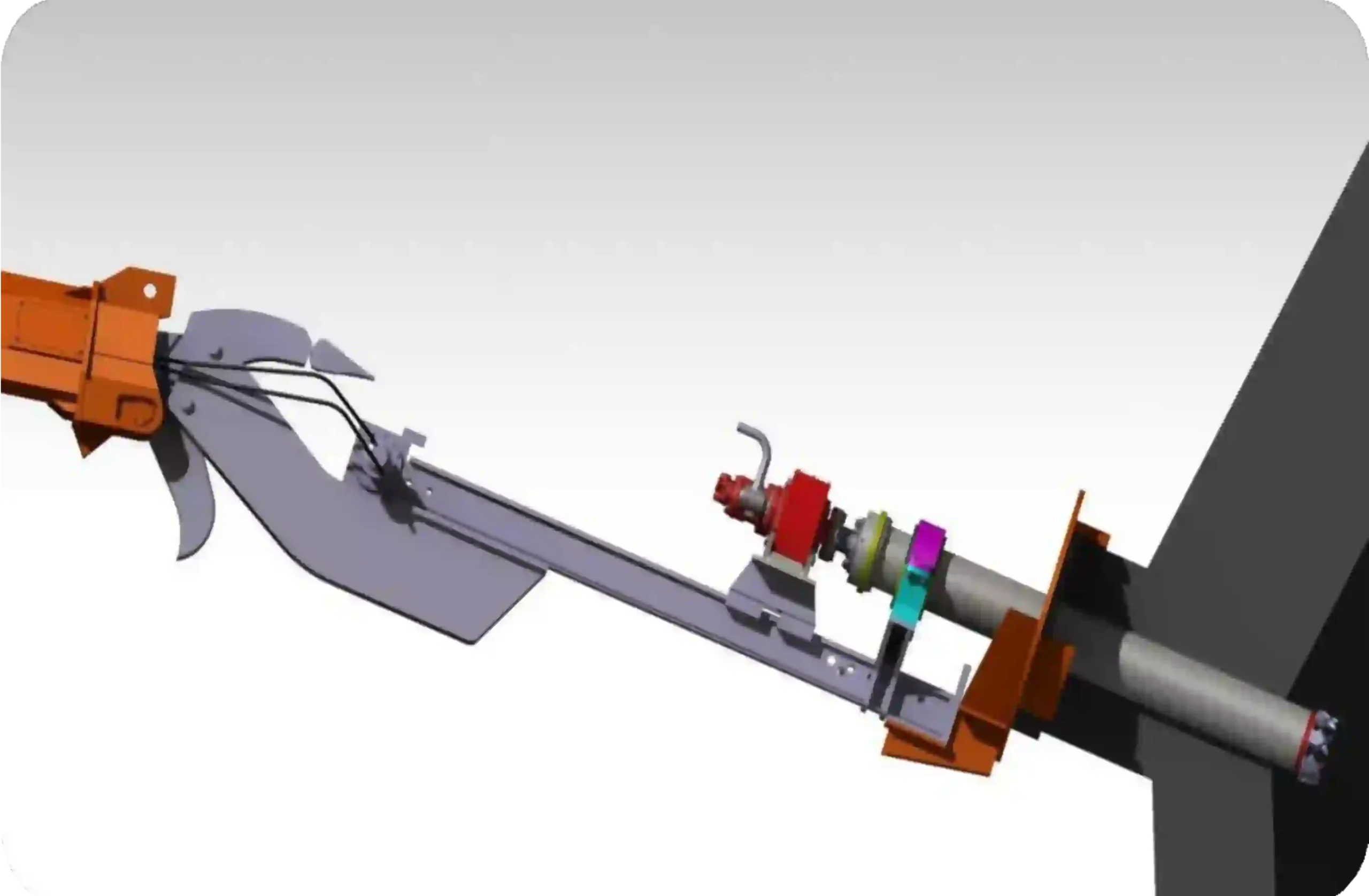

Zetko has created a budget friendly, multipurpose technology taphole renewal attachment type (CTRM-A).

-If you do not wish to invest in two exclusive machines: you can invest in CTRM-A. This attachment is compatible with your existing telescopic boom wrecking machine and you existing EBTRM

– Drilling time: 15 to 20 minutes depending on the plant conditions .

It moves forward and backward and does not require TBWM boom rotation and boom stroke

– It can be interchanged within 5 minutes, with the use of our mechanical quick coupler for TBWM machines reducing downtime and increasing productivity. Other tools can also be attached to this coupler technology for different purposes

– Drill bits are provided based on the application needs: Solid drill bit, TC bits drill, fine cutter drills and many more.

– New taphole can be inserted using the resleeving attachment

Sundrilla (Taphole Drilling Attachment)

Zetko has created an economical solution to perform taphole drilling operation: Sundrilla, which ensures 100 % safety.

– This application can be used with new or existing Telescopic boom rotations for drilling. It also helps forward and backward movement for TBWM.

– Drilling time: 15 to 20 minutes

– This attachment is run by a hydraulic motor and does not need boom rotation for drilling.

– It can be interchanged within 5 minutes, with the use of out mechanical quick coupler reducing downtime and increasing productivity.

– Drill bits are provided based on the application needs: Solid drill bit, TC bits drill, fine cutter drills and many more.

Converter Tap hole Renewal Machine(CTRM)

Eccentric Bottom Tap hole Renewal Machine

We have two versions of machines for EBT operation. Our machine is a telescopic boom ladle debricking machine having Volcadrila attachment to perform EBT renewal.

Follow our YouTube channel

ZETKO

ZETKO- DKV TECHNIK(INDIA) PRIVATE LIMITED

ZETKO TECHNOLOGIES LLC. USA

(Formerly ZETKO MASCHINENBAU GMBH, GERMANY)

ZETKO TECHNOLOGIES LLC. USA

(Formerly ZETKO MASCHINENBAU GMBH, GERMANY)

Contacts

Phone:

+91 8688401799

+91 8297144476

E-Mail:

sales@zetko.us

bluesky@zetko.us