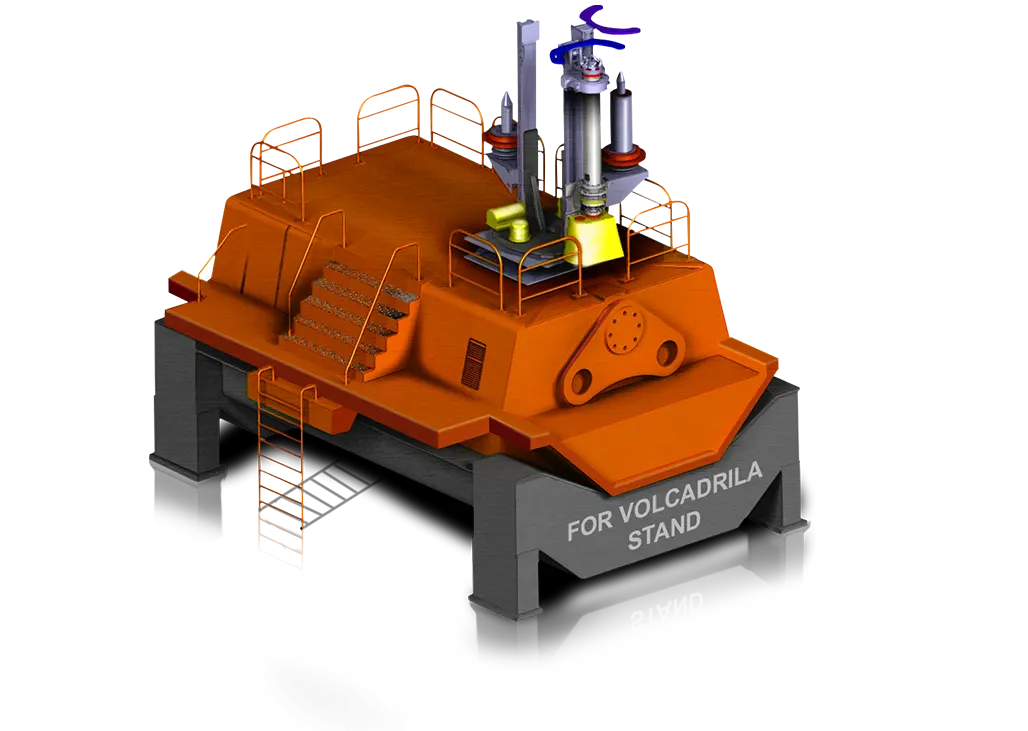

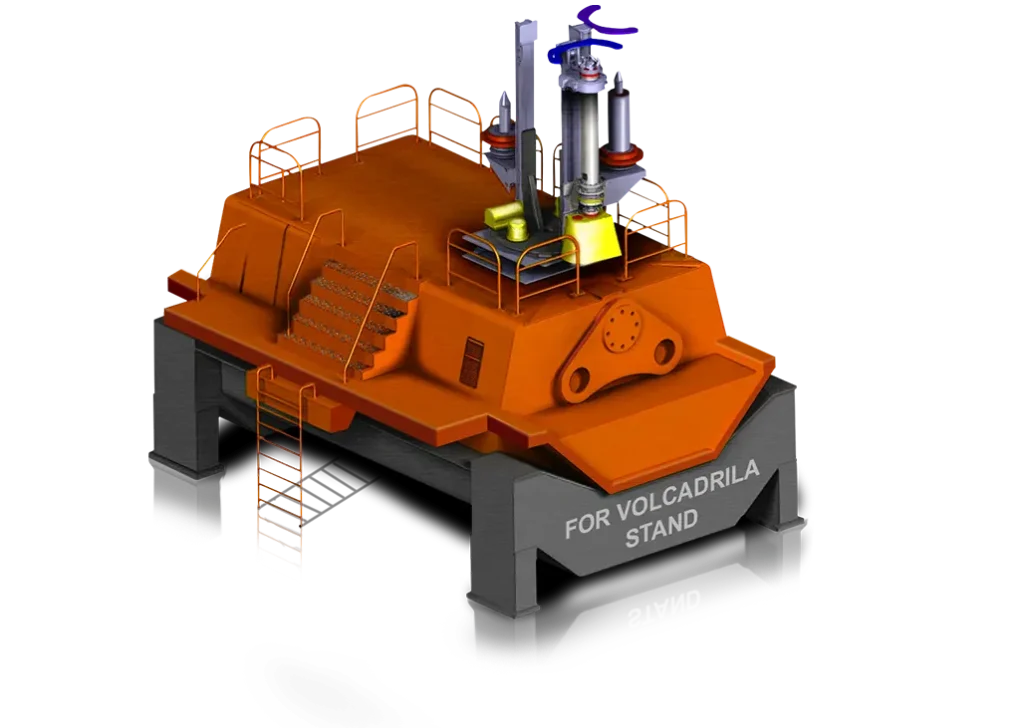

Deslagging Machines

Deslagging ensures efficient heat transfer & prevents build-up inside furnaces & ladles. Automated deslagging improves product quality, reduces refractory wear.

Deslagging

Deslagging ensures efficient heat transfer and prevents build-up inside furnaces and ladles.

Machines Used:

🔹 Slag Skimming / Raking Machine (SSM)

🔹 TBWM

• TBWM (for heavy deslagging in runners or torpedo ladles)

• Custom boom stroke and paddle design based on furnace size.

• Remote operation and protected hydraulic hoses ensure long equipment life.

Automated deslagging increases efficiency, improves product quality, and reduces refractory wear.

🔹 Slag Skimming / Raking Machine (SSM)

🔹 TBWM

• TBWM (for heavy deslagging in runners or torpedo ladles)

• Custom boom stroke and paddle design based on furnace size.

• Remote operation and protected hydraulic hoses ensure long equipment life.

Automated deslagging increases efficiency, improves product quality, and reduces refractory wear.

Follow our YouTube channel

ZETKO

ZETKO- DKV TECHNIK(INDIA) PRIVATE LIMITED

ZETKO TECHNOLOGIES LLC. USA

(Formerly ZETKO MASCHINENBAU GMBH, GERMANY)

ZETKO TECHNOLOGIES LLC. USA

(Formerly ZETKO MASCHINENBAU GMBH, GERMANY)

Contacts

Phone:

+91 8688401799

+91 8297144476

E-Mail:

sales@zetko.us

bluesky@zetko.us