Eccentric Bottom Tap hole Renewal Machine

Eccentric Bottom Tap hole Renewal Machine

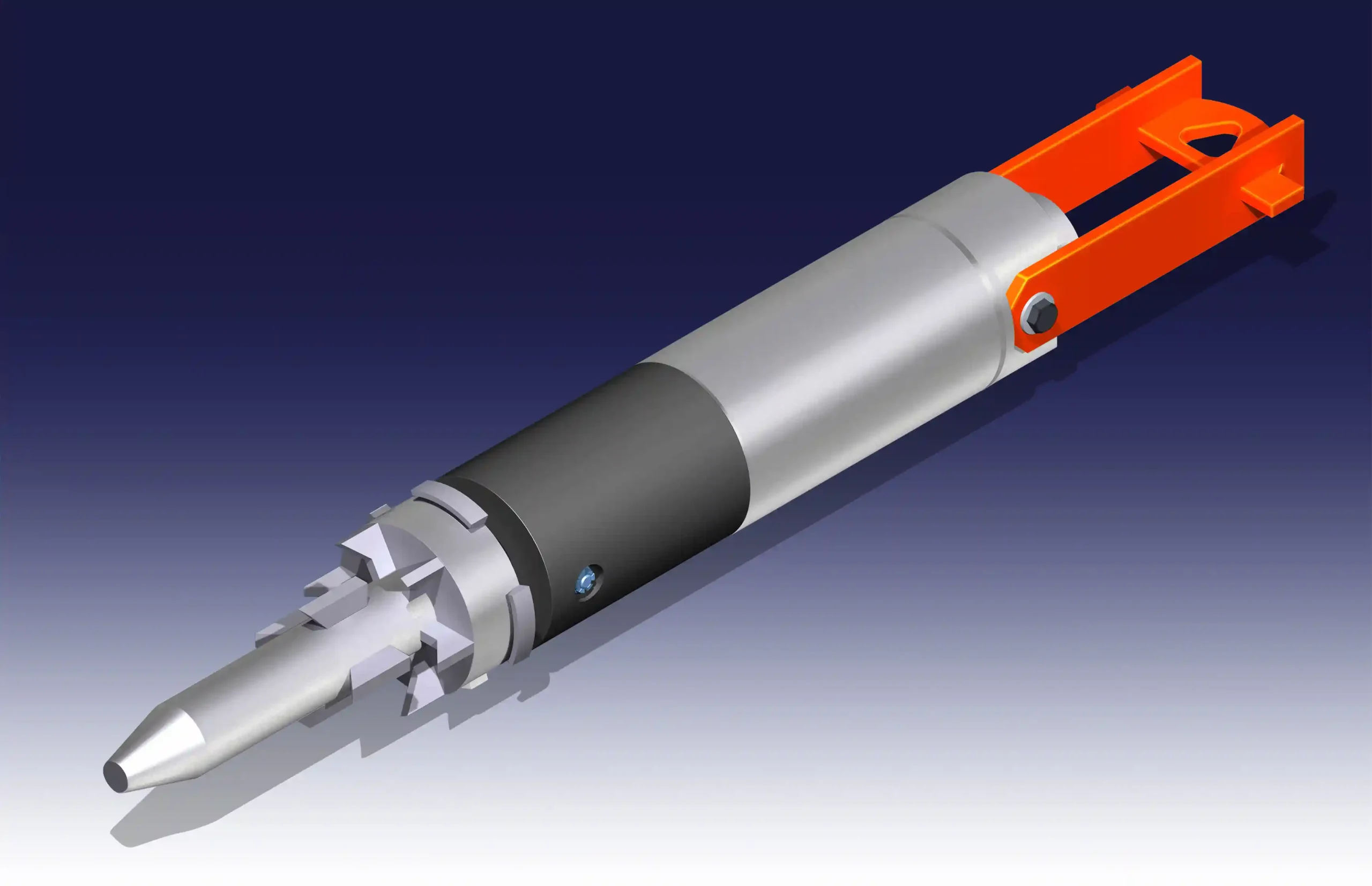

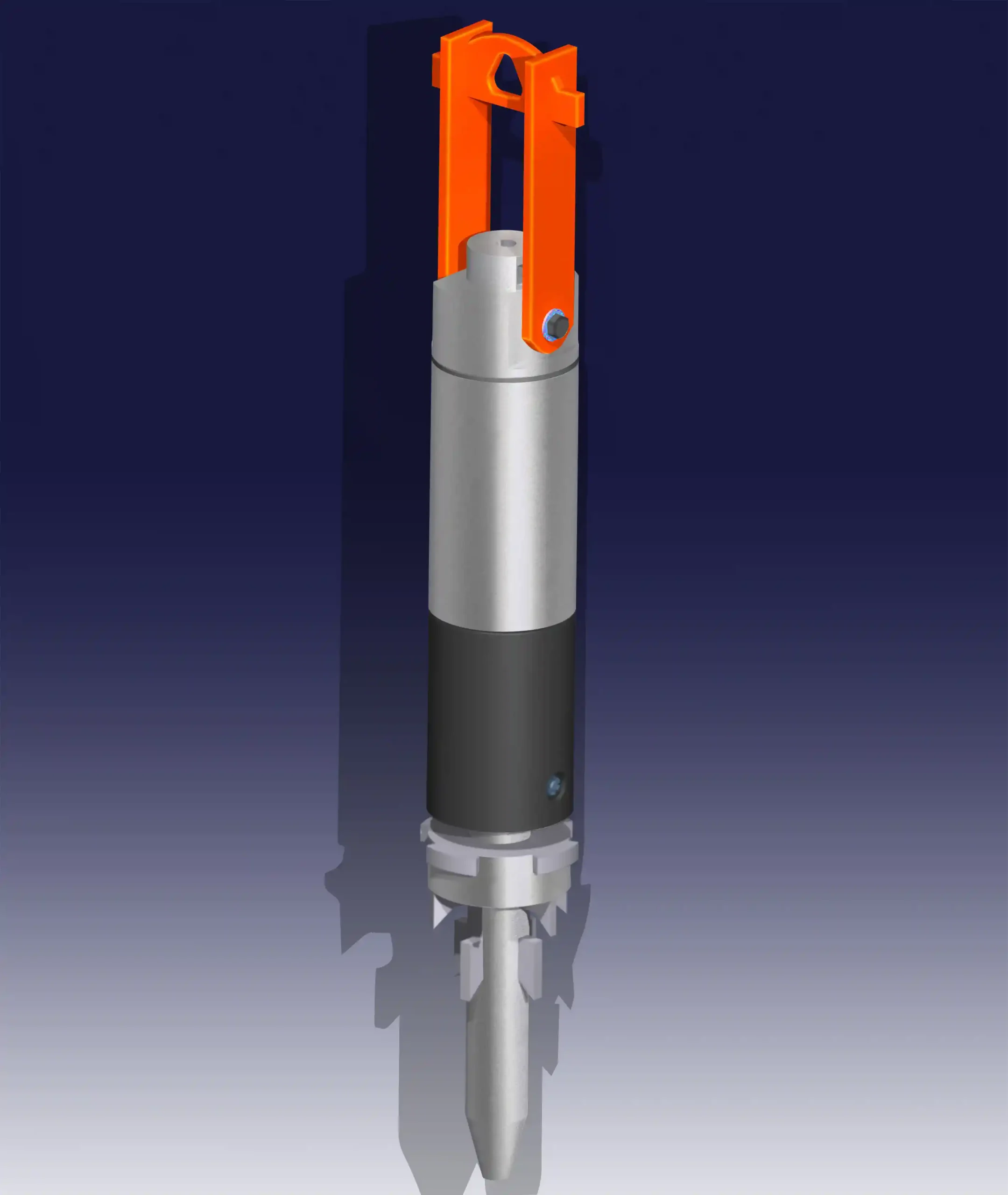

EBT renewal machine (Volcadrilla A)

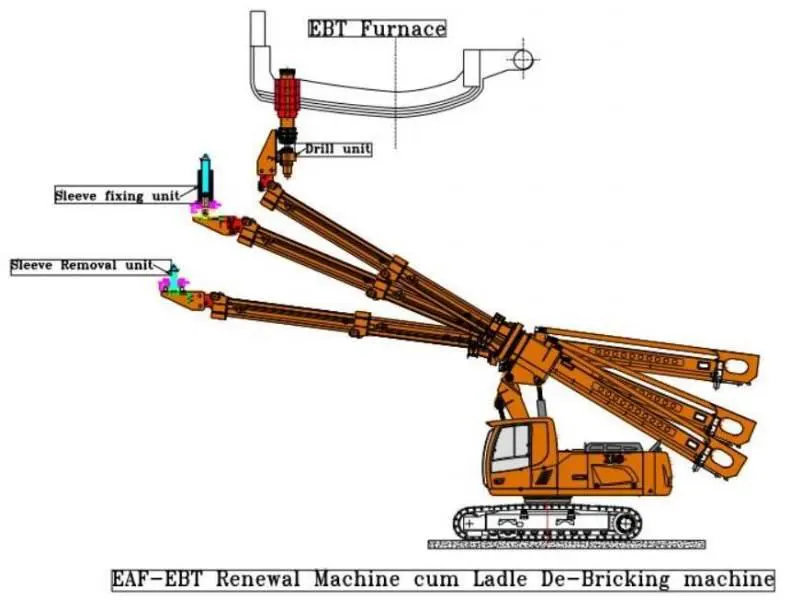

Volcadrilla EBTRM- A used for EBT end plate removal, taphole drilling and new taphole sleeve fixing operation. With different attachments, you can get different features: Ladle debarking, EAF hearth cleaning, mouth jam cleaning and Launder jam cleaning operations.

Key Features

- This equipment can be used for existing or new TBWM.

- Tools/ attachments can be changed in 5 minutes or less with Zetko’s quick coupler technology.

- Assigned workers can also use the retractable platforms by adding remote to make precise operations.

Eccentric Bottom Tap hole Renewal Machine (EBTRM)

Zetko Telescopic Machines available with options Diesel or Electrical Power, Tyre or Crawler, with cabin or with remote or combined operations, Articulation or Non-articulation.

- Volcadrilla A

- Volcadrilla L

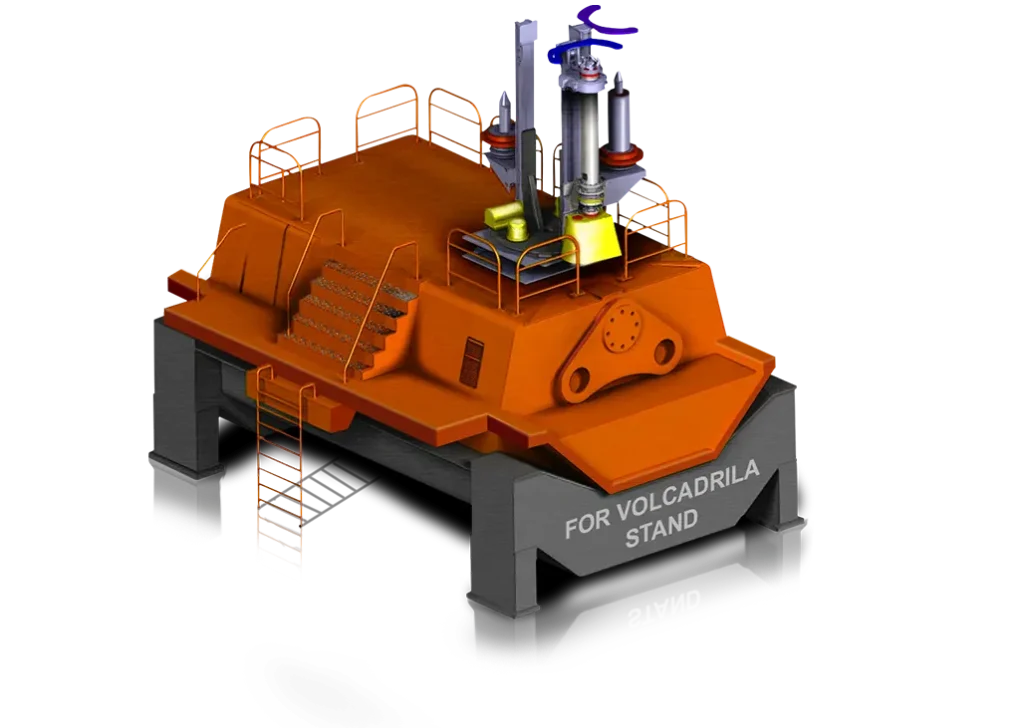

Volcadrila-A on TBWM

When to use TBWM?

Multifunctional jobs possible with

different attachments for ladle

and EAЕ

Equipment General Specification

Mode of Operation: Electrically Driven

Electrical Motor: Induction Motor 90 kw (50Hz) @ 1500 RPM, 400 Volts.

Hydraulic Tank Capacity: 200 Ltrs.

Max Flow Rate Pump: 180 LPM

Working Pressure: 180 Bar

Power Pack Cooling System : Air Cooled/ water cooled

Ambient Temperature: 50°C

Max Torque: 9000 Nm

Pressure: 240 bar

Nominal Flow: 120 lpm

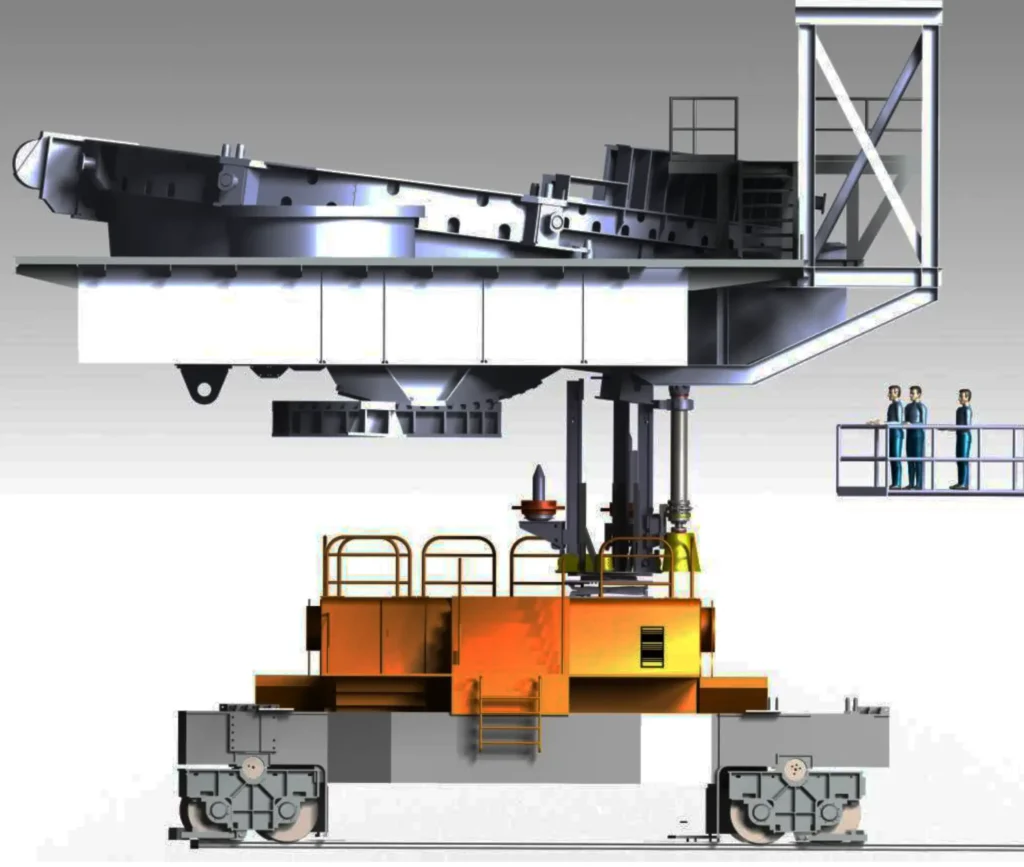

Volcadrila-A on AWM(Arm Wrecking Machine)

When to use TBWM?

Interchangeable with breaker for

other breaker related applications.

Equipment General Specification

Mode of Operation: Electrically Driven

Electrical Motor: Induction Motor 90 kw (50Hz) @ 1500 RPM, 400 Volts.

Hydraulic Tank Capacity: 200 Ltrs.

Max Flow Rate Pump: 180 LPM

Working Pressure: 180 Bar

Power Pack Cooling System : Air Cooled/ water cooled

Ambient Temperature: 50°C

Max Torque: 9000 Nm

Pressure: 240 bar

Nominal Flow: 120 lpm

Complete Solution EBT Renewal

- End Plate Removal

- Taphole worn-out taphole drilling/ breakout

- New Sleeve Insertion

Features:

- Volcadrila-A with quick coupler (< 3 min) with Telescopic Boom wrecking machine (TBWM)

- Zetko TBWM and AWM are interchangeable with other attachments for other applications

Compact EBT renewal machine for space-constrained

EAFs. Mountable on ladle car or track with inbuilt

power pack.

Functions

- End Plate Removal

- Taphole Drilling

- Sleeve Insertion

Benefits

No need for a seperate TBWM/

AWM

Equipment General Specification

Mode of Operation: Electrically Driven

Electrical Motor: Induction Motor 90 kw (50Hz) @ 1500 RPM, 400 Volts.

Hydraulic Tank Capacity: 200 Ltrs.

Max Flow Rate Pump: 180 LPM

Working Pressure: 180 Bar

Power Pack Cooling System : Air Cooled/ water cooled

Ambient Temperature: 50°C

Max Torque: 9000 Nm

Pressure: 210 bar

Nominal Flow: 150 lpm

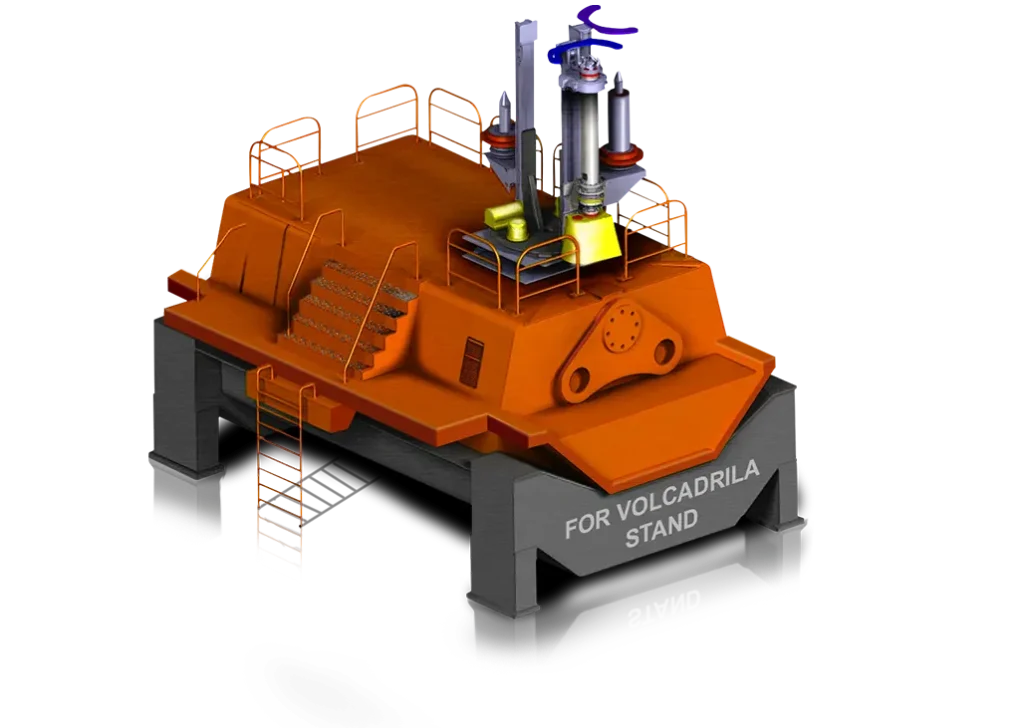

EBT renewal machine (Volcadrilla-L)

Volcadrilla- L is designed keeping in mind about the space constraints or lack of space under the EAF for EBT maintenance. This equipment can be placed on your existing ladle car or on the track. Moreover, it is equipped with a power pack to perform EBT renewal operations.

Functions: end plate removal, EBT tap hole drilling, and new tap hole sleeve fixing operations.

Functions: end plate removal, EBT tap hole drilling, and new tap hole sleeve fixing operations.

Key Features

- It ensures safety and increases productivity by reducing EAF downtime.

- The complete equipment is user friendly and remote-operated.

- Exclusive-purpose machine with lower investment compared to Volcadrila -A combined with boom de-bricking machine.

EBT Breakout Hammer

Hydraulic hammer tool for safe and fast removal of worn or jammed EBT sleeves.

- Eliminates manual chiseling

- Minimizes risk to operators

- Reduces EAF maintenance time

Eccentric Bottom Tap hole Renewal Machine

Slag Skimming Machine

SSM is used to remove the slag formed on the surface of the molten metal in the ladle KR/hot metal desulphurization process aluminum and copper furnaces.

Follow our YouTube channel

ZETKO

ZETKO- DKV TECHNIK(INDIA) PRIVATE LIMITED

ZETKO TECHNOLOGIES LLC. USA

(Formerly ZETKO MASCHINENBAU GMBH, GERMANY)

ZETKO TECHNOLOGIES LLC. USA

(Formerly ZETKO MASCHINENBAU GMBH, GERMANY)

Contacts

Phone:

+91 8688401799

+91 8297144476

E-Mail:

sales@zetko.us

bluesky@zetko.us