Electric Arc Furnace (EAF)

Electric Arc Furnace (EAF) maintenance involves periodic renewal of the EBT (Eccentric Bottom Taphole), end plate replacement, and cleaning of hearth and launder areas.

Electric Arc Furnace (EAF)

EAF maintenance involves periodic renewal of the EBT (Eccentric Bottom Taphole), end plate replacement, and cleaning of hearth and launder areas.

Machines Used:

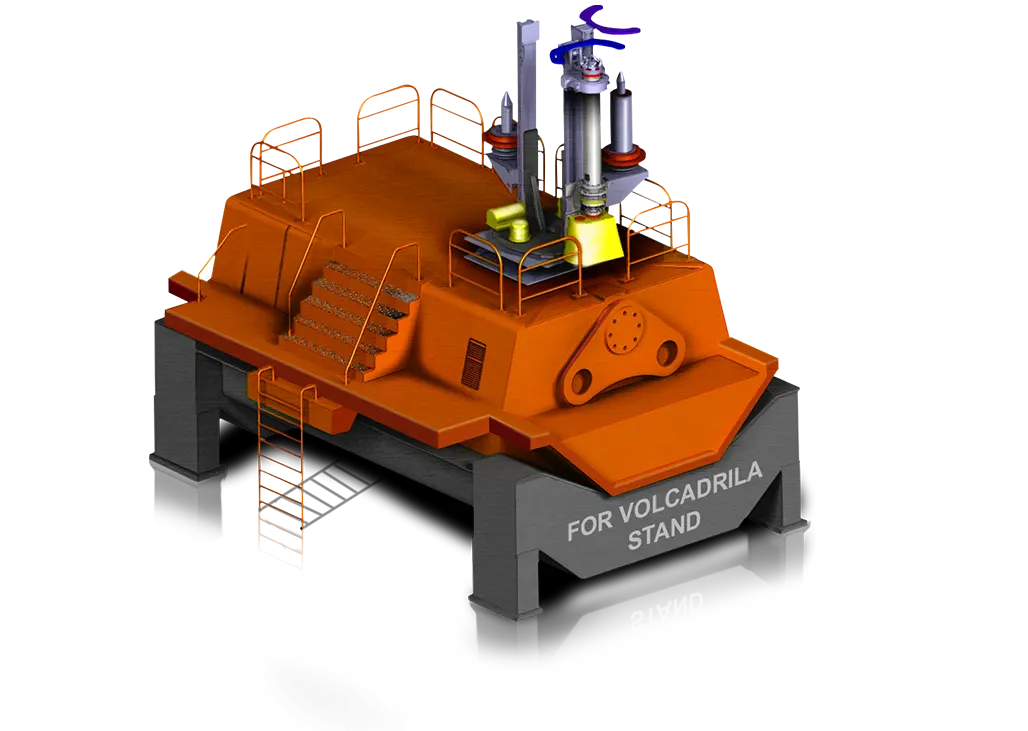

🔹 EBTRM (Volcadrila-A)

• Performs EBT renewal, drilling, and sleeve fixing.

• Uses Quick Coupler for fast tool change between tasks.

• Operated remotely for high precision and worker safety.

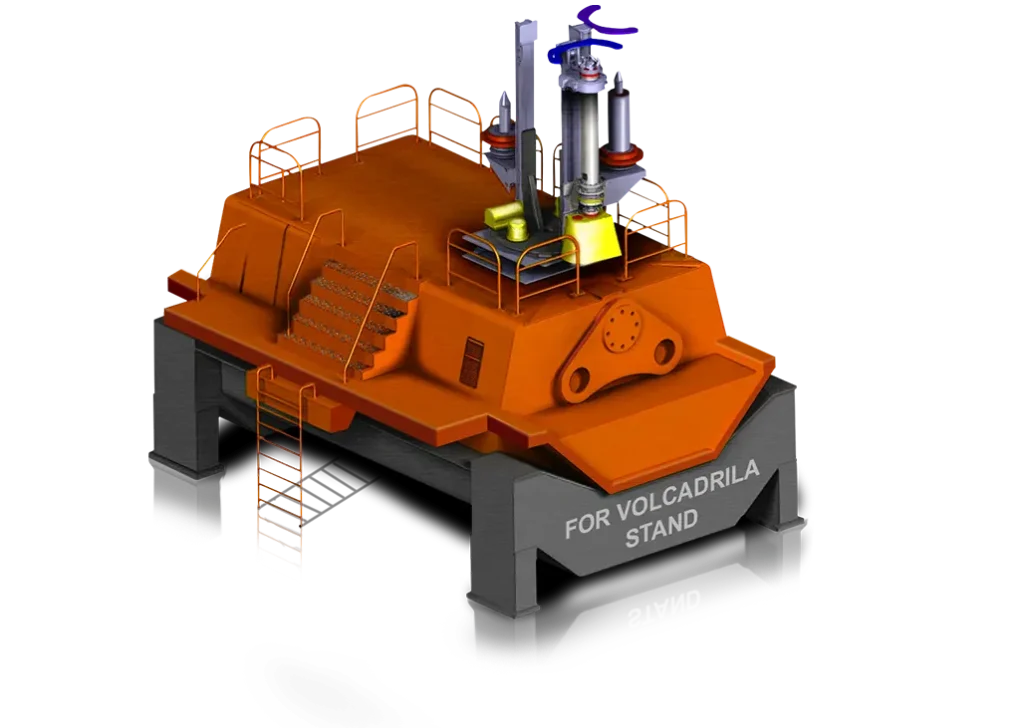

🔹 Volcadrila-L (EBT Renewal Machine on Ladle Car)

• Ideal for space-constrained EAF areas.

• Can be installed on existing ladle cars or maintenance tracks.

• Fully remote operated with onboard power pack.

These EAF systems minimize downtime and deliver consistent maintenance results.

🔹 EBTRM (Volcadrila-A)

• Performs EBT renewal, drilling, and sleeve fixing.

• Uses Quick Coupler for fast tool change between tasks.

• Operated remotely for high precision and worker safety.

🔹 Volcadrila-L (EBT Renewal Machine on Ladle Car)

• Ideal for space-constrained EAF areas.

• Can be installed on existing ladle cars or maintenance tracks.

• Fully remote operated with onboard power pack.

These EAF systems minimize downtime and deliver consistent maintenance results.

Follow our YouTube channel

ZETKO

ZETKO- DKV TECHNIK(INDIA) PRIVATE LIMITED

ZETKO TECHNOLOGIES LLC. USA

(Formerly ZETKO MASCHINENBAU GMBH, GERMANY)

ZETKO TECHNOLOGIES LLC. USA

(Formerly ZETKO MASCHINENBAU GMBH, GERMANY)

Contacts

Phone:

+91 8688401799

+91 8297144476

E-Mail:

sales@zetko.us

bluesky@zetko.us